Our Industrial Series Brush Cutter incorporates a completely new design for increased production, maximum reliability and ease of maintenance. This industry leading design incorporates a direct drive system for smoother and more quiet operation. The 1/4" steel "clean deck" design with high quality powder coat helps keep the deck clear of debris and is easier to clean and maintain. The alternating bevel blade design provides a deep penetrating self clearing cut. Blades are made of 3/4" thick high grade steel with a reversible design for added blade life.

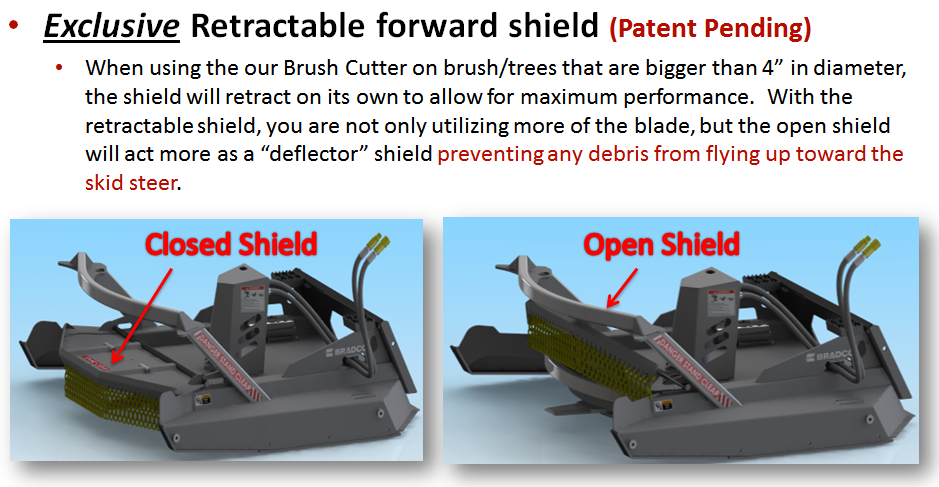

This unit is designed for clearing medium to heavy density brush and hardwoods up to 10” diameter (30-45 GPM models) from wooded acreage, road right-of-ways and pipeline maintenance. The exclusive, patented retractable forward cutting shield moves up and back to expose the entire cutting edge of each blade as it comes in contact with a tree or heavy brush. This pioneered feature provides additional safety protection for the operator and work-site while greatly minimizing flying debris. Standard replaceable stump grinding carbide teeth (Included as standard equipment) increase mulching performance and allow stump removal from path. Replaceable bottom skid rails (included as standard equipment) are easily replaceable and eliminate the mainframe from wear and damage.

Pressure gauge is used for essentially two purposes. The first use is when cutting heavy ground cover or brush where you would want to maintain a performance level without going into relief. The second function is when stump grinding or felling large trees and you want to make use of the inertia generated by this cutters heavy flywheel like blade carrier. To do this you need to know when you are back up to full speed. Use the pressure gauge to identify a steady state unloaded pressure of about 1,000 to 1,200 psi. At this pressure the cutter is back up to full rpm and ready for work. Note: the pressure gauge is rubber isolated.

Blade Retention Bolt hex shank is designed to prevent the bolt from rotating under extreme cutting conditions. Direct drive with controlled shut down on this line of brush cutters include special hydraulic valving to shut the cutter head down quickly and safely. There is a distinct audible sound during the shutdown which will indicate to the operator that the blades are coming to a stop. This sound can be minimized by throttling back slowly prior to shutting off the auxiliary hydraulics. Direct drive offers less moving parts to maintain, a drop in motor alignment, and better efficiency. High torque motors are used on these units to improve efficiency and recovery times.

Please select the Hydraulic Fittings size to match your machines fitting from either 1/2", 5/8" or 3/4" Flat Face Couplers before adding item to the cart. (Please specify size of case drain coupler as well)

Features

● Exclusive patented retractable cutting forward shield (Patent Pending). When using the Industrial brush cutter on brush/ trees that are bigger then 4” in diameter, the shield will retract on its own to allow for maximum performance

● Standard pressure gauge indicator comes standard on this unit and is easily visible to the operator helps prevent excessive stalling and overheating

● Heavy duty push bar pushes trees away from the operator and provides additional control when felling trees

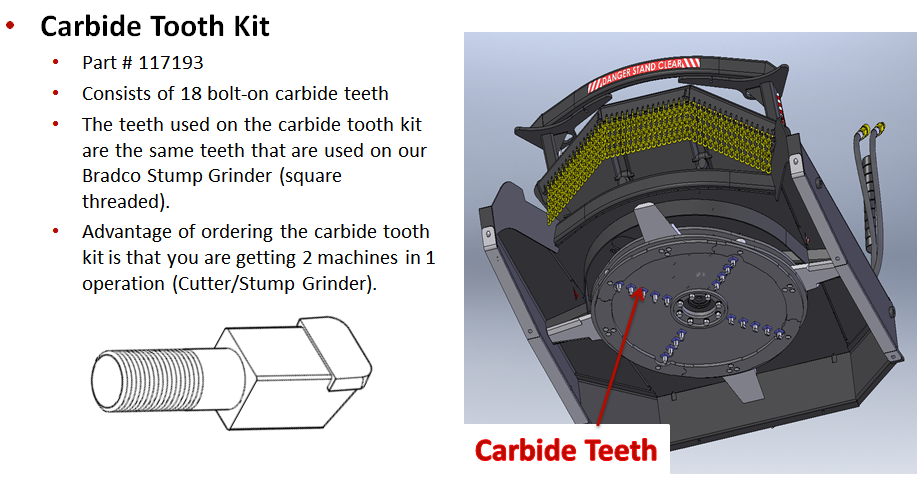

● Optional bolt-on carbide stump grinding teeth increases mulching performance and take the stump down to ground level

● Four double bevel reversible edge blades machined from AR400 high strength steel for maximum cutting power durability

Heavy construction allows for lower center of gravity and better stability on hillsides.

*Wear Items, Hoses, and Couplers are not covered under warranty

Videos Hide Videos Show Videos

Shipping & Delivery Terms of Notice and Agreement

Special Note: Please be advised that all shipments and deliveries require the following:

1. Shipping and handling charges are based on the total weight of your order. Oversized or excessively heavy items may have an additional shipping cost. This charge may not be calculated until the order is being prepared. We will notify you if there is an increase in the shipping charge on your order prior to billing and shipping.

2. We ship via Old Dominion, XPO Logistics, Estes, UPS, FedEx, US Postal Service, or Broker Hire Subcontractors in the continental US. Shipments to Alaska, Hawaii, Canada, and overseas will have additional shipping costs applied.

3.Please allow around 4-30 business days for delivery of non-back ordered items in the continental US. Please also allow additional time for shipments to Alaska, Hawaii, Canada, and/or any international orders.

4. Entire orders will be shipped together, when and if possible.

5. Someone MUST be present to receive the delivery and to sign the receipt of goods.

6. It is required that a machine be present with the proper lift capacity to off-load freight as lift-gate service is NOT provided unless otherwise agreed to and paid for in advance.

7. No re-consignments or deliveries to other locations or addresses will be permitted once an order has been placed and the delivery address has been confirmed. In the rare case a client demands this, additional fees will be applied and must be paid in full prior to delivery of goods.

8. It is the client’s responsibility to call the shipping company to arrange a time of delivery. We DO NOT guarantee that any prior-notice call or notice will be given once the order ships.

9. Any non-commercial ship-to-address will incur additional fees. In addition, any other special delivery requests such as Lift-Gate Service, Residential Address, Limited Access, Inside Delivery, Notify/Call Ahead Notice on Delivery, Secure Access, Job site or Construction Site, Farms or remote area deliveries will incur additional fees.

10. It is the client’s responsibility to inspect goods upon their arrival. In the rare case of receiving an item that has been damaged during transit, it is the client’s responsibility to note any and all damage on the Bill of Lading (BOL). We encourage you to take photos to document any damage and to notify Spartan Equipment via email at orders@spartanequipment.com. Clients will also be responsible for filing a freight claim with the carrier. Spartan Equipment will do everything we can to be an advocate on your behalf and assist in negotiating with the carrier to remedy the situation.

11. In the equally rare case of a lost shipment, please notify us if you have not received your order in a timely manner. Our goal is to stock the majority of items we advertise to sell and meet our client’s needs promptly. If your order has been lost in transit, we will work with the carrier to find it. Please give us up to two weeks to notify the carrier about the issue and to locate your order.

12. Transactions shipped within the state of Maryland are subject to Maryland State Sales Tax. Items picked up at our facility within Maryland MUST be done via appointment only and are also subject to State Sales Tax.