Working with Concrete: How Skid Steer Concrete Breakers Break Through the Toughest Jobs

Posted by Lee Padgett on 3rd Jun 2024

Ever stared down a stubborn concrete slab, wondering how on earth you'll break it up? Maybe you're renovating a basement, or perhaps a demolition project awaits. Whatever the reason, concrete removal can feel like a daunting task.

But don’t worry! Skid steer concrete breakers, also known as hydraulic hammers, are powerful skid steer attachments that can pulverize concrete with impressive efficiency.

This article dives deep into the world of skid steer breakers, exploring their capabilities, applications, and how they work alongside other attachments to streamline your concrete removal process. So, grab your hard hat and let's get cracking!

The Power of the Punch: Understanding How Skid Steer Breakers Work

Skid steer breakers pack a serious punch. They utilize a hydraulic piston that delivers rapid, forceful blows to the concrete, fracturing it into manageable pieces. Here's a breakdown of the key components:

- Hydraulic System: The lifeblood of the breaker, the hydraulic system channels the power of your skid steer's engine to the piston.

- Piston: This powerful component rapidly extends and retracts, delivering the hammering action that breaks apart the concrete.

- Tooling: Different attachments, like chisels and points, are mounted on the end of the breaker to optimize its performance for specific tasks.

The force generated by a skid steer breaker is measured in foot-pounds per blow (ft-lbs). Generally, higher ft-lb ratings indicate greater breaking power, suitable for thicker or tougher concrete. When choosing a skid steer breaker, consider the size and type of concrete you'll be working with.

What Are the Different Applications for Skid Steer Breakers

While demolition is a primary function, skid steer concrete breakers have a wider range of uses:

- Secondary Breaking: After initial demolition with a larger hammer, a skid steer breaker can be used to further reduce concrete chunks into smaller pieces for easier removal or recycling.

- Trenching: For utility projects or foundation work, skid steer breakers can break up tough ground or asphalt, making trenching more manageable.

- Road Maintenance: Breaking up damaged roads or sidewalks for repairs is another common application for skid steer breakers.

- Rock Breaking: In some cases, skid steer breakers can be effective for breaking up smaller rocks or uneven surfaces.

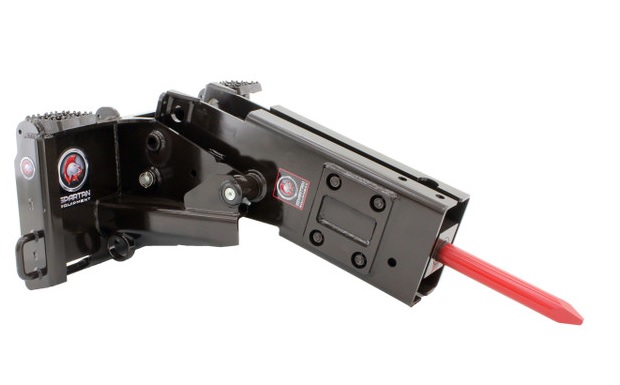

Spartan Skid Steer Breaker Models: Powerhouse Options for Any Project

Now that we've explored the general applications of skid steer breakers, let's delve into the specifics of two popular Spartan Skid Steer Breaker models: the SE500 and SE750. Understanding their features and how they compare can help you choose the perfect tool for your concrete removal needs.

Spartan SE500 Skid Steer Concrete Breaker:

The SE500 is a versatile hydraulic concrete breaker ideal for mini-excavators, compact utility loaders, and many skid-steer applications. Here's a breakdown of its key features and specifications:

- Impact Energy: 500 ft-lbs. This rating makes the SE500 suitable for breaking up medium-thickness concrete or asphalt.

- Operating Weight: 1120 lbs. This lighter weight allows for easier maneuverability on smaller skid steers.

- Working Steel Diameter:63 in. This diameter is compatible with standard chisels and points for various breaking tasks.

- Flow and Pressure Requirements: The SE500 operates within a range of hydraulic flow rates (10-21.9 gpm) and pressures (1595-2117 psi). Ensure your skid steer's hydraulic system can meet these requirements for optimal performance.

- Recommended Carrier Range: 5,000 - 13,500 lbs. This model is ideal for skid steers within this weight range.

Spartan SE750 Skid Steer Concrete Breaker:

For tougher concrete or larger demolition projects, the SE750 offers increased breaking power:

- Impact Energy: 750 ft-lbs. This significant increase in impact force allows the SE750 to tackle thicker concrete or heavily reinforced slabs.

- Operating Weight: 1230 lbs. Slightly heavier than the SE500, the SE750 provides additional stability during operation.

- Working Steel Diameter:67 in. This diameter accommodates standard tooling for the SE750.

- Flow and Pressure Requirements: The SE750 operates with a similar flow rate range (11.9-21.9 gpm) but a slightly higher pressure range (1566-2175 psi) compared to the SE500. Again, ensure compatibility with your skid steer's hydraulic system.

- Recommended Carrier Range: 7,000 - 15,900 lbs. The SE750 is suited for skid steers within this weight range for optimal performance.

Choosing the Right Spartan Skid Steer Concrete Breaker:

Both the SE500 and SE750 offer valuable features like:

- No back head charging: This simplifies operation and reduces downtime.

- Durable design: Features like increased front head wall thickness and CD designed side bolt threads enhance the breaker's longevity.

- Versatile tooling: Both models come with a Moil Point and can accommodate various chisels and points for specific tasks.

- Complete package: Spartan breakers include essential accessories like hoses and couplers, minimizing additional purchases.

How Skid Steer Breakers Work with Other Skid Steer Attachments

Skid steer breakers are just one piece of the concrete removal puzzle. Here's how they can work alongside other skid steer attachments to streamline your project:

- Skid Steer Loaders: After the breaker has done its job, a skid steer loader with a bucket attachment can efficiently scoop up and remove the broken concrete pieces.

- Grapple Buckets: For larger concrete chunks or debris, a grapple bucket attachment on your skid steer can securely grab and transport the material.

- Sorting Buckets: Sorting buckets can be helpful for separating concrete debris from dirt or other materials, simplifying disposal or recycling.

Choosing the Right Tools for the Job: Selecting a Skid Steer Attachment

With various skid steer attachments available, selecting the right ones depends on your specific project needs:

- Concrete Thickness and Strength: Consider the thickness and hardness of the concrete you'll be breaking. A higher ft-lb rating breaker is ideal for thicker or reinforced concrete.

- Project Scope: Think about the overall size and scale of your project. For extensive demolition, a larger breaker may be necessary.

- Skid Steer Compatibility: Ensure the chosen skid steer breaker is compatible with the size and capacity of your skid steer loader.

- Attachment Options: Explore the different tooling options available for your skid steer breaker, such as chisels with varying widths or blunt points for specific tasks.

Safety First: Essential Tips for Operating Skid Steers

Skid steer breakers are powerful machines, and safety is paramount. Here are some crucial tips to remember:

- Wear proper personal protective equipment (PPE): This includes safety glasses, gloves, hard hat, sturdy boots, and ear protection.

- Maintain a safe working distance: Always stand clear of the breaker while it's operating.

- Be aware of your surroundings: Watch out for overhead hazards and ensure nobody is in the vicinity of the breaker while it's in use.

- Conduct regular inspections: Inspect the skid steer breaker and its attachments for wear and tear before each use.

- Follow the manufacturer's instructions: Always refer to the user manual for specific operating guidelines and safety precautions.

The world of concrete removal doesn't have to be a one-size-fits-all approach. With various skid steer attachments and concrete breaker models, you have the power to choose the right tools for your specific needs.

Partner with a knowledgeable equipment supplier like us at Spartan Equipment, and together you can conquer any concrete challenge, big or small.